Product Features

Adopting silicon piezoresistive sensor, integrated compact structure, economical and low-cost design, remote transmission of 4~40mA output gas and electricity

Cable technology mode, high measurement accuracy, inherently safe, suitable for industrial production, site exploration, and deep water level in mines

Measure the liquid level of municipal water conservancy facilities.

Working principle

The pressure sensor probe is placed in the measured liquid and subjected to a certain static pressure of the medium (P). This pressure is related to the measured liquid

The liquid level height (h, m) of the body is proportional to P=ρ gh (Pa), where ρ is the specific gravity of the medium (g/cm3) and g is

The local gravitational acceleration (m/s2) is constant for the measured medium and location, where ρ and g are constant. The electronic components of the transmitter will apply pressure

The liquid level pressure signal measured by the force sensor is transmitted to the display instrument, and the liquid level signal of the medium is displayed through circuit conversion.

Technical Parameter

·Measurement range

Minimum 0~0.5m, maximum 0~350m

·Measurement accuracy

0.5% FS (comprehensive error including linearity, hysteresis, and repeatability)

·Long term stability

Better than 0.25% per year

·Allowable medium temperature

-20℃~80℃

·Allow ambient temperature

-40℃~85℃

·Allow storage temperature

-40℃~85℃

·Temperature influence

0.5% accuracy level, less than 0.25% per 10K

·Material of the part in contact with the medium

·Silicon piezoresistive sensor

Corrugated film 316L (special requirements agreed upon)

·Measuring sensor housing

Stainless steel 304

·Air conducting cable

polyurethane

·Sensor counterweight

Stainless steel 304 (special requirements agreed upon)

·Material of non-contact parts with the medium

·Junction box

ABS plastic IP65

·Safety jacket

Nickel plating on carbon steel

·Electrical parameters

Working voltage (12.5~30V DC)

·Signal output

Analog two-wire system 4-20mA

·Cable entry hole

Internal thread M20 × 1.5 (special requirements agreed upon)

·Analog cable

Three core instrument cable

·Allow environmental humidity

95%HR

Exterior structure

Electrical connection

load characteristics

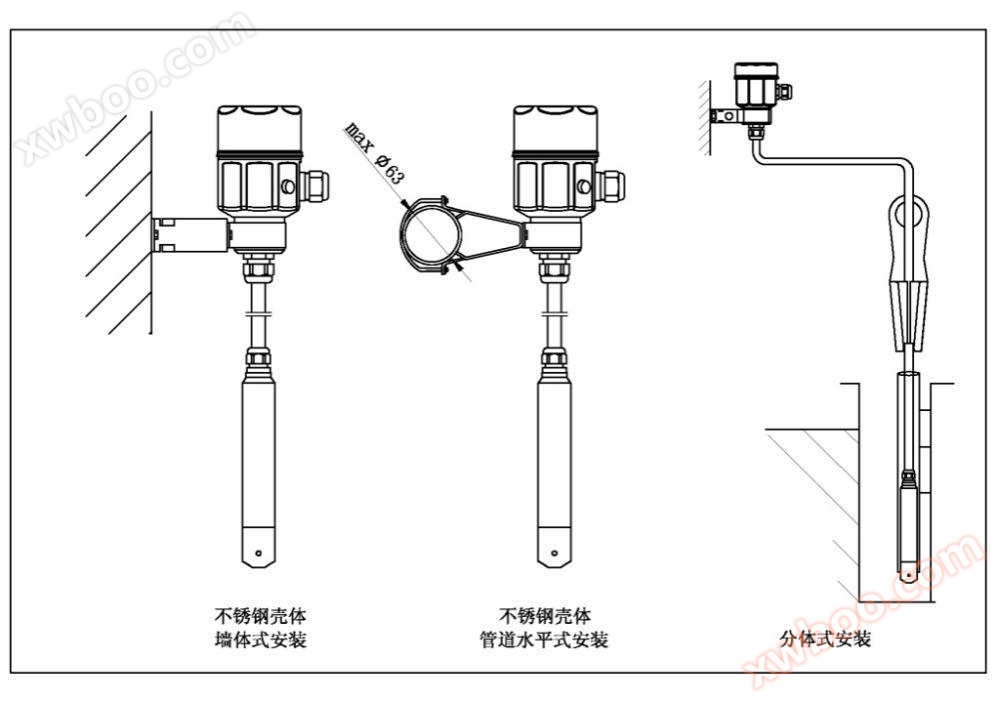

Installation method

Communication protocol

DB series intelligent liquid level gauge with remote communication function

Overlay a digital signal on the 4-20mA two-wire output signal of the level gauge transmitter to achieve the HART communication protocol standard

Several functions. The functional implementation includes the following: manual operation using the HART communication protocol or a microcomputer (requires configuration)The HART communication protocol software interface can remotely calibrate the zero point and full range values of the liquid level transmitter, display the temperature value of the medium, and indicate whether it has been usedPressure level value, adjust damping value, achieve self diagnostic function of the measurement system, display various fault states represented by fault codesLocation and reason.

Order Selection Table